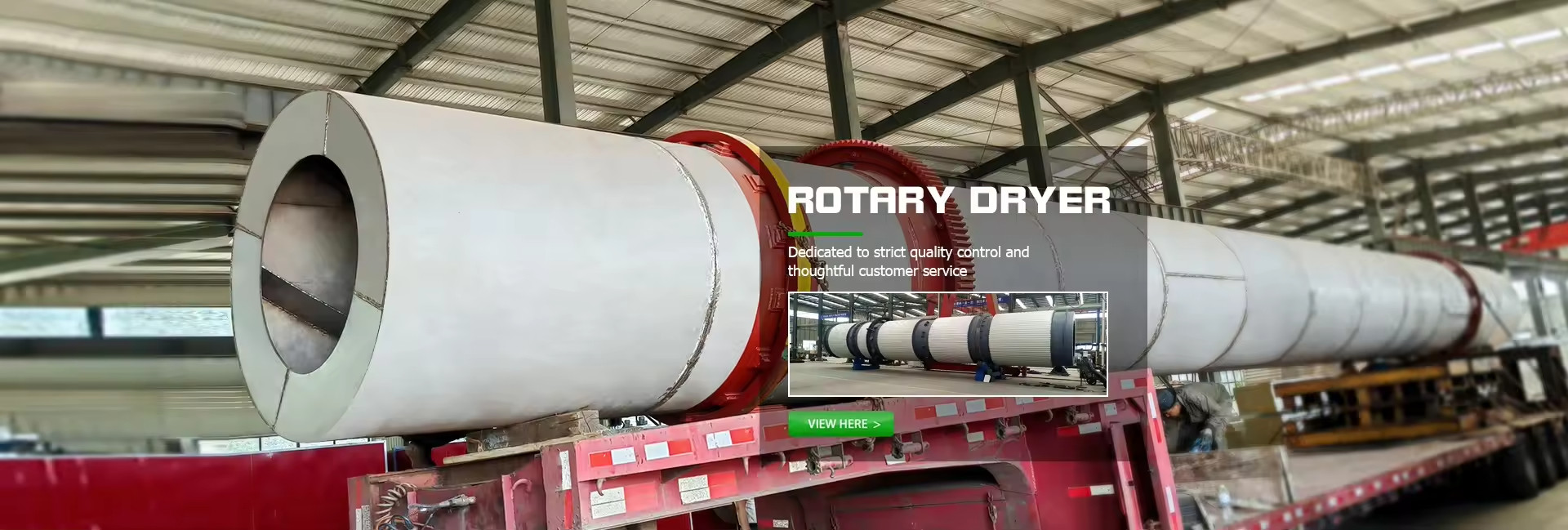

Working Principle and Core Characteristics of Wood Chip Rotary Dryer

The wood chip rotary dryer is a key piece of equipment in industries such as wood processing, biomass pellet preparation, and edible mushroom substrate treatment. Its core function is to stably reduce the moisture content of wet wood chips (35%-60%) to the required 8%-15% through a continuous heat and mass exchange process. Its working mechanism is based on the synergistic effect of the equipment structure and thermal process, mainly encompassing four core aspects: heat source supply, material movement, gas-solid heat exchange, and intelligent control. Each aspect is precisely designed to form a closed-loop system.

I. Core Working Principle

1. Heat Source System and Heat Medium Generation

The equipment adopts a multi-source adaptable heat source design, compatible with various energy forms such as electric heating tubes, natural gas, coal, and biomass fuels (e.g., wood chip scraps). Heat energy is converted into a clean heat medium—drying hot air with a controllable temperature of 120℃-280℃—through a tubular heat exchanger, avoiding direct contact between fuel combustion products and materials, thus preventing contamination. Indirect heating models isolate the flame from the material through a heat exchanger, increasing heat utilization by over 20% compared to direct heating models; some high-end models can achieve a thermal efficiency of 80%. The heat source transmission pipeline is wrapped with insulation, controlling heat loss to within 5%, ensuring that heat energy is concentrated inside the drum.

2. Material Movement and Heat-Mass Exchange Process

Wet sawdust is continuously fed into a rotary drum (typically 0.8-2.4 meters in diameter and 3-24 meters in length) installed at a 3°-5° angle by a screw feeder. The transmission system drives a gear ring via a motor and reducer, causing the drum to rotate smoothly at 3-15 rpm. Spiral lifting plates (lifting plates) distributed on the inner wall of the drum repeatedly lift and scatter the sawdust as the drum rotates, forming a uniform material curtain. This ensures that each sawdust particle has sufficient contact with the hot airflow, increasing the contact area by 4-6 times compared to static drying.

Under the combined action of the lifting plates and the inclined angle of the drum, the material moves slowly along the drum wall in a spiral trajectory. The moving speed can be finely adjusted by the drum rotation speed to ensure that the material stays in the drum for 20-40 minutes, achieving gradient evaporation of moisture—first evaporating surface free water, then gradually removing internal bound water, ultimately controlling the moisture content fluctuation within ±1%.

3. Airflow Organization and Moisture Separation and Discharge

High-temperature hot air, under the negative pressure of the induced draft fan, forms a counter-current or parallel flow with the material (counter-current flow is often used in biomass pellet production to improve thermal efficiency). The wet exhaust gas carrying water vapor enters the gas-solid separation system at the end of the drum. It first passes through a cyclone separator to remove more than 80% of large dust particles, and then is filtered by a bag filter, ensuring that the dust emission concentration is ≤10mg/m³, far below the national environmental protection standard of 30mg/m³. Some models are equipped with a finned waste heat recovery device, which can recover 30% of the heat energy in the exhaust gas for preheating cold air, further reducing unit energy consumption.

4. Intelligent Control and Process Stability Guarantee

The equipment is equipped with a distributed sensor control system. Humidity and temperature sensors are installed at the feed inlet, the middle section of the drum, and the discharge outlet to collect real-time data on material moisture content and hot air temperature, transmitting this data to the PLC controller. The system automatically adjusts three core parameters using frequency conversion technology: the feed rate of the screw feeder (0.5-5t/h, depending on the model), the heating power of the hot air furnace, and the airflow of the induced draft fan. When the discharge moisture content is detected to be too high, the system will simultaneously reduce the feed speed and increase the hot air temperature to ensure that the final moisture content is accurately met, avoiding material quality fluctuations caused by manual adjustments.

II. Core Product Characteristics

- Strong Structural Adaptability: The drum is welded from thickened steel plates, with a roller ring-thrust support structure, capable of withstanding the impact of wet materials and preventing horizontal displacement during tilted operation. Its continuous operating life exceeds 8000 hours. The lifting plate angle is optimized for material particle size, adapting to different specifications of wood chips from 0.1-5mm, with no significant adhesion or accumulation.

- Stable Drying Efficiency: Through optimized material curtain formation and airflow design, the drying intensity per unit volume reaches 20-35 kg/(m³·h), and the energy consumption per ton is controlled at 120-180 kWh when the moisture content is reduced from 50% to 12%, with a moisture content deviation of ≤1% between different batches.

- High Operational Safety: Addressing the flammable nature of wood chips, the system is equipped with explosion-proof doors, a nitrogen replacement system, and an oxygen concentration monitor. When the oxygen concentration inside the drum exceeds 5%, an automatic alarm is triggered, and inert gas protection is activated. The equipment's operating noise is ≤85 dB(A), meeting industrial noise standards.

- Convenient Operation and Maintenance: Adopting a modular design, the hot air furnace and dust collector can be independently inspected and maintained. The drum interior has no dead corners and is equipped with an automatic vibration dust removal device, requiring only a full cleaning once a month. Routine maintenance only requires checking the transmission system lubrication level and sensor calibration.

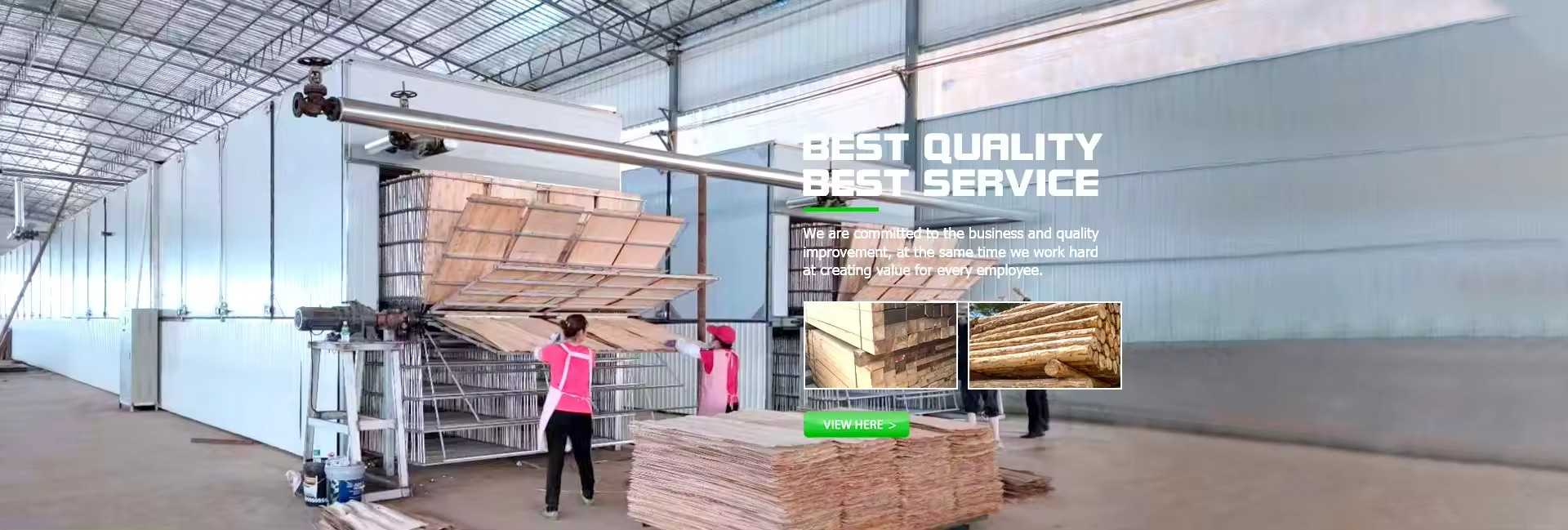

III. Core Advantages and Applications of Large-Scale Timber Drying Chambers

Large-scale timber drying chambers, as crucial equipment in the timber drying field, complement wood chip drum dryers. They are particularly suitable for batch processing of block and board-type timber. Their core advantages are reflected in their technical characteristics, production efficiency, and environmental friendliness, as detailed below:

1. Core Technical Advantages

- Energy-Saving and High-Efficiency Characteristics: Utilizing heat pump drying technology based on the reverse Carnot cycle principle, the core technology uses a small amount of electricity to drive the compressor, absorbing free heat from the air, saving over 60% more electricity than traditional electric heating equipment. The all-electric operation mode produces no combustion emissions, ensuring stable thermal efficiency and a coefficient of performance (COP) of 3-5, far exceeding that of traditional drying equipment.

- Controllable Drying Quality: Equipped with an intelligent temperature control system and a PLC programmable controller, the drying chamber's temperature (50-80℃), humidity (10%-20%), and airflow circulation speed can be precisely controlled, ensuring uniform drying of the timber both internally and externally, significantly reducing defects such as cracking and deformation. Supports high-temperature processing up to 75℃; constant temperature above 55℃ kills mold; 24 hours at 65℃ thoroughly eliminates discoloration and decay fungi, preventing wood deterioration at its source.

- Outstanding Production Efficiency: Equipped with a powerful convection circulating fan, hot air is evenly distributed and has strong penetration. No manual turning of the wood is required, shortening the drying cycle to 3-7 days per batch, several times faster than traditional natural drying or simple drying equipment, significantly reducing labor and time costs.

- Intelligent and Structural Advantages: Fully automated operation via a PLC computer system. It automatically matches the drying curve based on wood type (e.g., hardwood, softwood), board thickness, and other parameters, requiring no dedicated personnel. Modular installation design allows for easy assembly and disassembly, flexible floor space, and adaptability to various indoor and outdoor installation scenarios.

- Safety and Environmental Protection: The fully enclosed drying system eliminates the risk of electric shock. Equipped with multiple early warning devices and safety protection facilities, it completely avoids the fire hazards of traditional combustion drying. No combustion waste is emitted; all-electric operation meets food-grade hygiene standards and environmental policy requirements. - High economic applicability: The equipment is highly compatible, capable of drying various materials besides wood, including vegetables, fruits, medicinal herbs, and meats, significantly improving equipment utilization. Core components utilize imported compressors and high-quality parts, with a system design life of up to 15 years and low daily maintenance costs.

2. Main Application Areas

With its stable drying quality and batch processing capacity, this equipment is widely used in furniture manufacturing, building decoration panel processing, and solid wood flooring production. It is particularly suitable for processing high-end woods (such as mahogany, teak, and walnut) where strict requirements are placed on moisture content accuracy and appearance quality. It is a core supporting equipment for large-scale, high-quality wood production.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!